What aluminum extrusion finishes do we offer? What inspection methods and standards do we follow to ensure the quality of your aluminum extrusion designs? These questions and more about aluminum extrusion, finishing, and fabrication answered below.

Extruded Aluminum Finishing FAQs

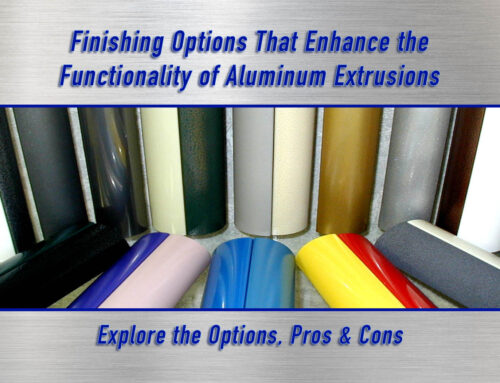

What aluminum extrusion finishes do you offer? / What aluminum finishing methods are available?

What’s the difference between anodized aluminum and mill finished aluminum?

Mill finished aluminum refers to extrusion products that have not undergone any surface treatment. Anodized aluminum is a mill finished aluminum that goes through the anodization, which is an electrochemical process that increases corrosion resistance, durability and decoration.

What aluminum machining options are available?

We have ten CNC machines, which have the capability of vertical and horizontal machining. Our ten CNC machines also have 4th-axis capabilities, which allows us to mill aluminum extrusions on multiple axes without having to change tooling, which increases productivity.

Aluminum Extrusion Profiles FAQs

What inspection methods and standards do you follow to ensure the quality of your aluminum extrusion designs?

We ensure the fabricated parts meet required specifications through meticulous inspection that includes creating custom gauging to ensure the fit and function of each part when necessary. We offer a wide range of aluminum extrusion services while preserving ISO 9001:2015 certifications across all of our manufacturing facilities.

Can you help me design a new aluminum profile?

Whether you come to us with a full fabrication print or just part of an idea, we can work with you to achieve your ideal design requirements. With the help of computer-aided design (CAD) and computer-aided manufacturing (CAM), we can help you execute your fabrication needs.

Is there a size limit on the aluminum extrusion profiles that you can produce?

Aluminum Extrusion Dies FAQs

What is the cost of a die?

There is no set cost to a die. Based on the customizations including size, shape and finishing, we will give a fair price.

What is the lifetime of an extrusion die? / How long does an extrusion die typically last?

We design dies to control heat and uneven pressure, which slows down the extrusion rate and extends the lifespan of a die. Eventually, dies will need to be replaced, but we absorb the cost of die replacements.

Can you use existing dies from other profile extrusions?

Depending on your specific application, we offer standard dies. If we have a standard die that fits your need, we’ll send you a profile print to review. If it works for your application, then we’ll run it for you.

Purchasing & Ordering FAQs

Can you cut extrusions to a specified length before shipping them?

We utilize a wide variety of procedures and techniques to configure specific aluminum extrusions by way of cutting, bending, deburring, welding, machining and forming to assemble your final product.

What is the minimum order quantity?

Typically, the minimum order quantity without set up charges is 1,000 pounds per mill finish.

What packaging options do you offer?

We use a wide variety of standard and custom packaging to ship your order any way you want, from bare bundle to totally enclosed, secure crates.