Star Extruded Shapes offers customers the ability to customize your aluminum solar racking system to your specifications and is a one stop shop from concept/design to production to finishing and to final delivery.

With solar power technology advancements, many people & companies are choosing to install solar panel racking systems at home or at their businesses. Solar racking is an ever-growing market, and in many states is heavily incentivized toward the consumer, as an attraction for implementation. Whether you are looking to do a rooftop install, or suspended above the ground, solar panels are everywhere. However, no matter where they are, they rarely sit flush with the surface. They are typically fixed to solar panel racks.

Star offers in-house capabilities for your preferred methods:

-

Precision tolerances on extruded profiles

-

Fabrication

-

CNC Machining

-

Assembly

-

Finishing

-

Custom packing & kitting

In addition to custom profiles designed by individuals or companies for their specific needs, the T-Slot option continues to be popular for many applications related to solar.

T-slot extrusions – The T-slot extrusion is a popular aluminum profile for solar panel mounting. The T-shaped slot makes it easy to slide pieces together and then allow for micro-adjustments. A simple T-track gives you a single track for flat installations. A more complex T-track design will allow for assembly and connection on up to four sides.

Strength

Strength is one of the most vital considerations when installing a solar racking system. The racking needs to support the weight of your solar panels—and then some.

Solar panels are expensive; the last thing you want is for them to come crashing down. A strong mounting system keeps your solar panels (and any snow or debris they collect) from collapsing. This strength is essential during storms and high winds. Advancements in aluminum technology have made the metal stronger than ever—without eliminating other benefits.

Aluminum has a high strength-to-weight ratio. In practice for functionality, this means that aluminum can withstand significant stress before it breaks. This comes with a weight that makes for easy install, lower maintenance & repair costs, and a green option for disposal and/or recycling post-use.

Durability & Corrosion Resistance

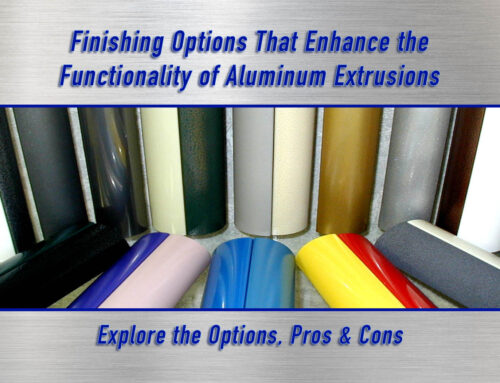

Solar panels are built to last—and the racking on which they’re mounted should be, too. Aluminum doesn’t rust, but unprotected varieties are prone to corrosion. Avoiding corrosion is simple with proper planning & maintenance, starting with the option of affordable protective coverings – the two most common that Star Extruded Shapes can offer to our customers. These finishes are:

- Powder Coat Paint – for racking and hinges

- Anodization – for panels and some racking applications

It should be noted that while unfinished aluminum may show corrosion or discoloration, is not a structural risk.

Application

For rooftop solar panels, aluminum is the ideal material. Weight is the number one consideration for roof-mounted solutions, and with its’ high strength to weight ratio, aluminum is undoubtedly the ideal lightweight choice. The same concept applies to adding solar panel racking systems to RV’s or campers or vans. For ground-mounted solar panels, using aluminum makes for easier handling and setup, for installation considerations.

Star Extruded Shapes offers superior quality aluminum extrusions from design to install Start the discussion today with one of our knowledgeable Sales Team members.

[email protected], or call us at (330) 533-9863