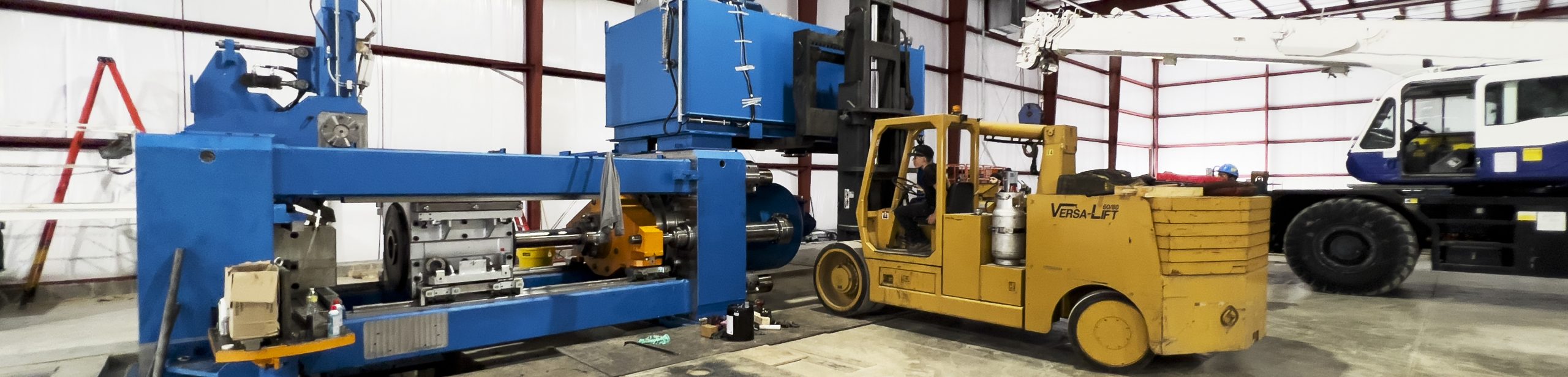

Get Your Orders in Ahead of Schedule, to Ensure a Quick Turnaround. The new press is installed along with a concrete billet pad with a 7-stage billet oven.

Star is on schedule and capacity is growing, lead times are improving.

We not only are we installing a brand new press, we now have nearly 50,000 sq/ft of wear-house space that could be potentially used for Star’s new stocking programs.

They say pictures are worth a thousand words, well scroll down to see the progress of our new press & facilities.

Talk to one of our knowledgable sales reps today, to get an RFQ or discuss how Star can provide a seamless process from start to finish for your project and specific needs.

or

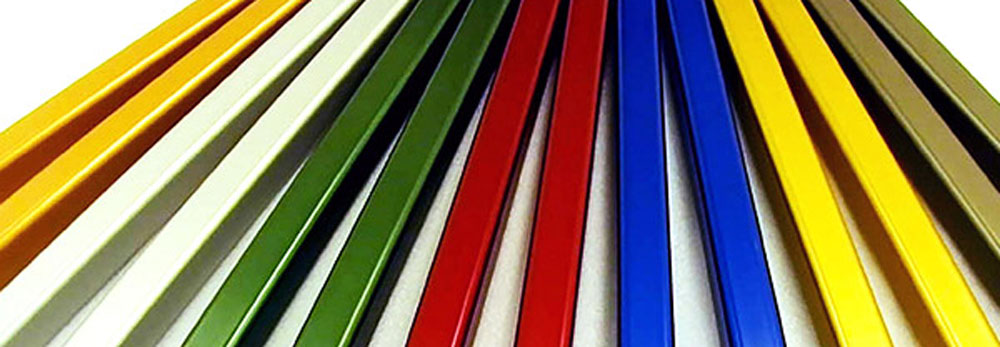

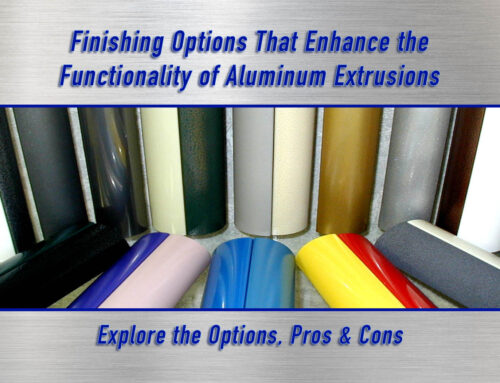

In the mean time, find out even more on our finishing capabilities by checking out our site & reading about powder coating.

Let us know if you have any questions or submit a RFQ for your next order.

or