Star Extruded Shapes, Inc. stands as your ultimate turnkey aluminum extrusion provider. If you’re on the lookout for a reliable and seasoned aluminum extrusion company, your search ends here. Situated in Canfield, Ohio, Star brings forth over 40 years of industry expertise, operating across three expansive manufacturing facilities totaling 350,000 square feet.

What truly sets Star apart is their all-inclusive approach to aluminum extrusion. They offer a wide array of services including design, engineering, extrusion, finishing, fabrication, and assembly. From the very beginning to the final stages, Star has all your extrusion requirements comprehensively covered.

Star boasts a storied legacy in the aluminum extrusion sector, renowned for their exceptional customer service and satisfaction rating. Their unwavering commitment to delivering high-quality extrusions with punctuality and at competitive prices has earned them a devoted clientele.

Aluminum Extrusion Manufacturing

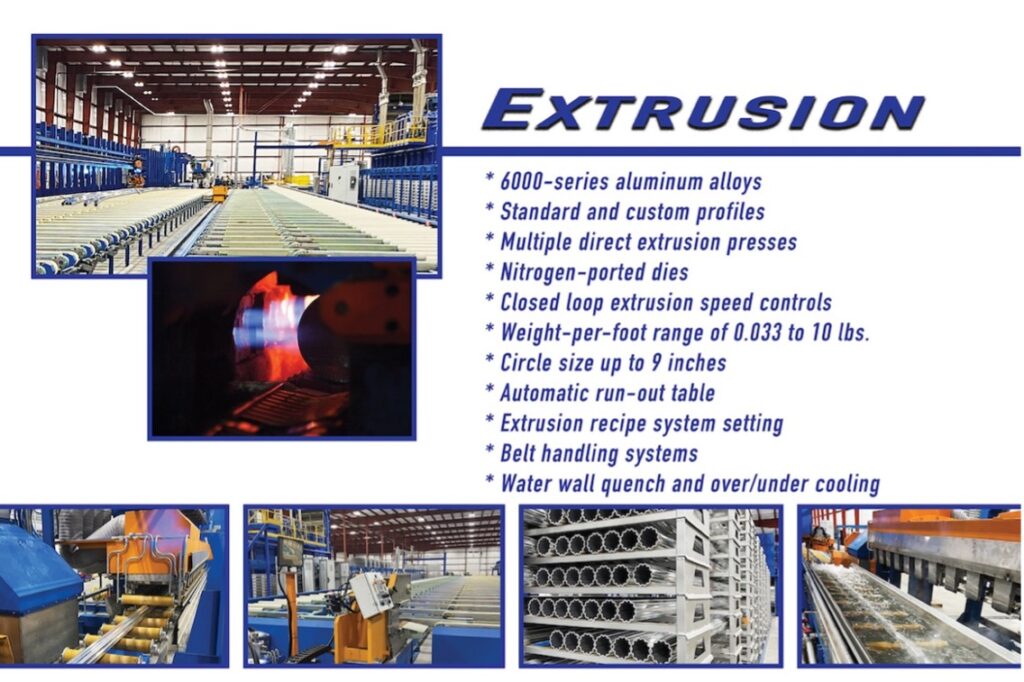

Star’s manufacturing facilities offer a wide range of aluminum extrusion services, with all their facilities certified with ISO 9001:2015 certifications. Their extrusion plant is spread across 277,000 square feet, featuring four aluminum extrusion presses of 6″, 7″, 8″ & 9″ inch diameter. This allows them to cater to the unique needs of various industries. With the versatility of presses, they can manufacture profiles of all sizes.

Star offers an experienced staff of engineers that can assist with design needs. Their engineers use advanced software applications such as computer-aided design (CAD) and computer-aided manufacturing (CAM) programs to help design the extrusion that will work best for the application.

Star’s aluminum extrusion services are ISO 9001:2015 certified and include 6000-series aluminum alloys, standard and custom profiles, multiple direct extrusion presses, nitrogen-ported dies, closed-loop extrusion speed controls, weight-per-foot range of 0.033 to 10 lbs., circle size up to 9 inches, automatic run-out table, extrusion recipe system setting, belt handling systems, water wall quench, and over/under cooling.

Custom Aluminum Fabrication

Star’s aluminum fabrication process is cutting-edge, involving various techniques and aluminum alloys to fabricate different product types, giving customers significant advantages over other materials.

Their certified facility offers extensive capabilities, including conventional punch presses, horizontal and vertical machining centers, sheet metal forming, laser cutting, vibro deburr, and lineal deburr. They also have ten advanced CNC machines, including 4th-axis capabilities, which enable them to mill aluminum extrusions on multiple axes without changing tooling, increasing productivity.

Star prides itself on providing turnkey solutions to manage all aluminum extrusion needs, from small prototype jobs to high-volume production runs. They offer finishing and assembly services, such as powder coating, anodizing, and wet paint. Their laser-cutting capabilities ensure greater accuracy and speed, saving customers time and money.

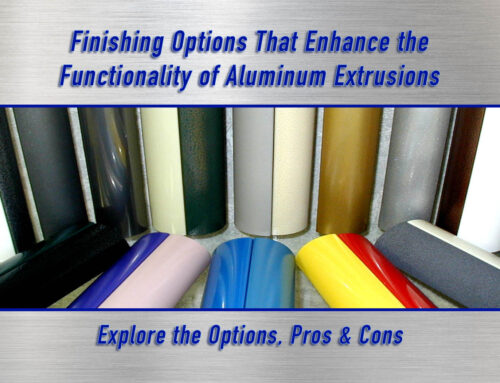

Aluminum Finishing Services

As your one-stop aluminum extrusion provider, Star offers unparalleled finishing services. Drawing from over 20 years of experience in powder coating, they employ cutting-edge techniques to provide high-quality RoHS-compliant coatings and treatments. Their capabilities include handling parts up to 30 feet long through a horizontal powder line, coupled with a dry-in-place, non-chrome sealer pretreatment that guarantees optimal corrosion resistance.

Star’s combination of infrared and convection ovens guarantees a faster powder cure. Whether you need stock or custom powders, this top-tier aluminum extrusion provider has everything you need to meet your functional or aesthetic requirements.

Complete Assembly

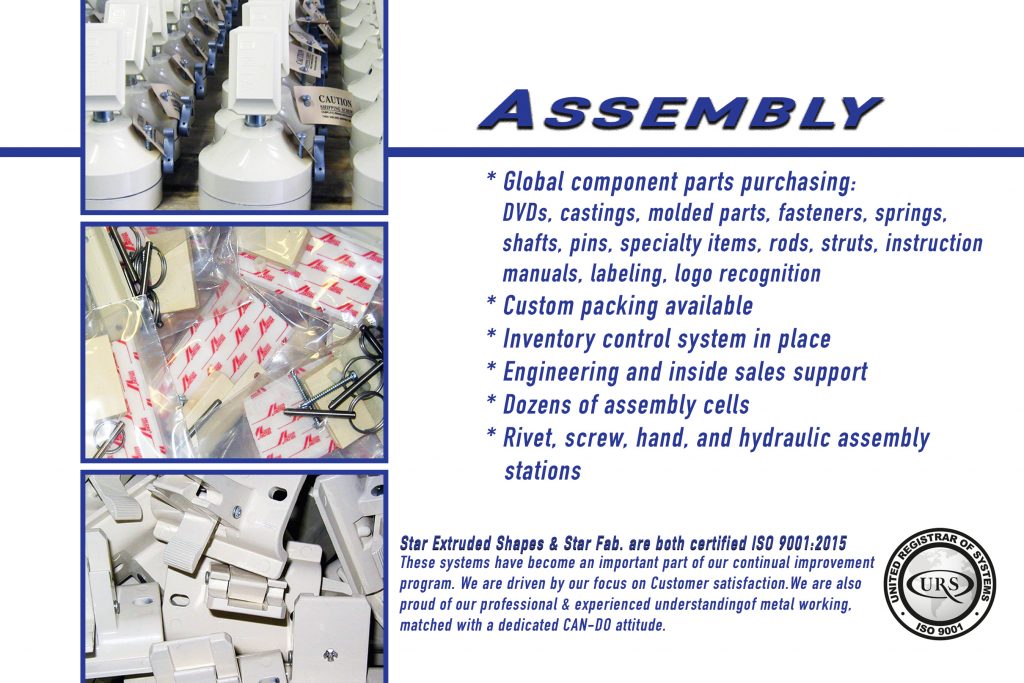

Their comprehensive turnkey process covers everything from design to finish, including assembly for all order sizes. This saves you both time and money. They’ll even handle the final product shipment to your customers, freeing you from involvement. With their purchasing power for components on a global scale, they can ensure the most cost-effective assembly of your product.

Their assembly capabilities are extensive and include the following:

- Global purchasing of parts such as DVDs, castings, molded parts, fasteners, springs, shafts, pins, specialty items, rods, struts, instruction manuals, labeling, and logo recognition

- Custom packing options

- Inventory control system that is fully operational

- Inside sales support and engineering assistance

- Dozens of assembly cells to meet your needs

- Various assembly stations, including rivet, screw, hand, and hydraulic.

Rest assured that their assembly process is top-notch and unmatched in the industry. Trust them to provide you with the best possible service.

Packaging and Shipping

Star offers a vast array of standard and customized packaging solutions to meet shipping needs, whether a bare bundle or a completely enclosed, secure crate is required. With hundreds of packaging specifications, they can quickly and efficiently handle shipments of any size. Their delivery service guarantees the timely arrival of freight. The company consistently loads its modern trucks with high-quality products, and they confidently exceed customer satisfaction.

Star’s Fully Automated Line

The automated system allows extrusions to go through all processes without human intervention. This guarantees minimal human error and maximizes efficiency. Additionally, there are inline packing stations to pack materials right after they exit the press.

The new 4th press has impressive capabilities, including a 3,000-ton press, a 9-inch circle size, adding 20-25 million pounds of capacity, max lengths of 25-35 feet, max weight per foot of 10 pounds, max profile width of 17 inches, and a max profile height of 9 inches.

Star, as a topnotch aluminum extrusion provider, understands the importance of staying ahead of the curve. That’s why they have a state-of-the-art manufacturing facility with the latest equipment. Their dedicated employees are committed to providing quality extrusions and exceptional customer service every step of the way.

If you’re looking for a great partner for your aluminum extrusion needs, look no further than Star. Their long history of experience, wide range of capabilities, commitment to quality and customer service, and state-of-the-art manufacturing facility make them the perfect choice for businesses of all sizes.

More about Star Extruded Shapes:

Star takes pride in its customer service department, which strives to provide timely and accurate communications to its valued customers. They aim to establish long-lasting customer relationships by ensuring their expectations are met and exceeded.

Their commitment to quality is unwavering, and they are constantly improving their processes, products, and services to ensure that they deliver the best possible experience to their customers. Star provides compassionate and sympathetic support to all its customers, ensuring that it meets their needs in every way possible.

Let’s Connect!

Facebook: https://www.facebook.com/profile.php?id=100063753529991

LinkedIn: https://www.linkedin.com/company/star-extruded-shapes