Let’s walk you through Star’s extruded aluminum fabrication options…

What is the Aluminum Fabrication Process?

Aluminum fabrication is the process of transforming extruded aluminum into finished parts. At Star, this begins by extruding aluminum — pushing an aluminum billet through a die to create various profiles like tubes, bars, or custom shapes. Once the extrusion is complete, fabrication begins, which may include punching holes, welding, or further shaping. Essentially, aluminum extrusion fabrication refers to any work done on the extruded profile.

Star utilizes a wide variety of procedures and techniques to configure aluminum extrusions by way of cutting, bending, deburring, welding, machining, and forming to assemble your product. Aluminum alloys offer unmatched advantages over other alternative materials that allow our team to fabricate a variety of product types in-house.

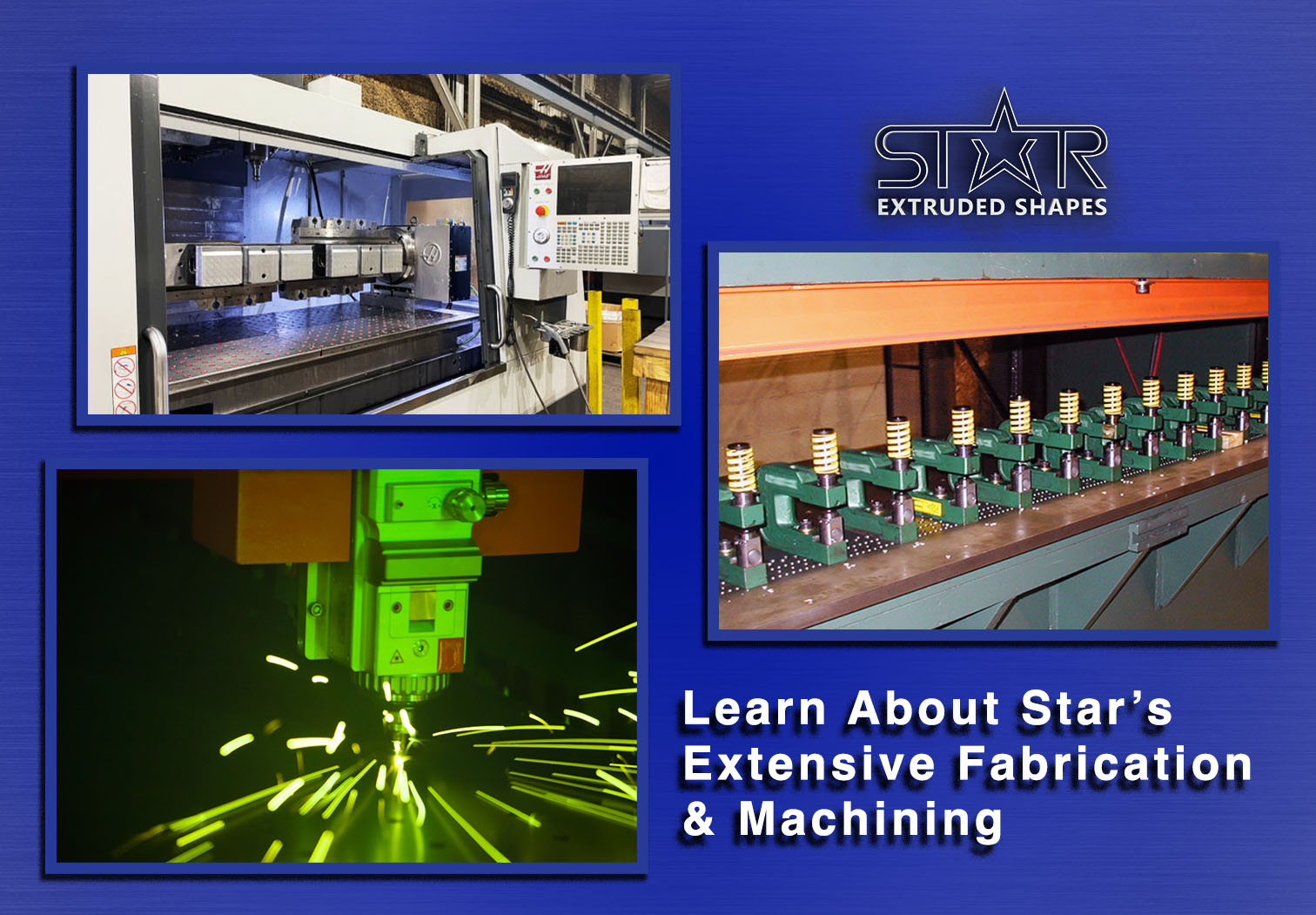

Aluminum Fabrication at Star Extruded Shapes

Over Star’s 40+ years in business, they have developed a niche for supplying fabricated and machined components, ready to assemble for their customers. With a 100,000 sq ft fabrication facility, Star has processes for general fabrication, CNC machining (vertical and horizontal), long-length material machining, and assembly services. Star’s offering of rapid prototypes and short run samples, enhances their value as a one-stop shop for the aluminum extrusions.

Cut-to-size:

- Star cuts over 6,000,000 pieces per year

- Equipment is automated & precise

- They can cut 0.250” to 30’-0”

- Star can hold as close as ±0.005”

- .400” to 20’ cut size lengths with +.010” tolerances

- Laser cutting

Presses:

- Multiple punch presses in-house, ranging from 15-Ton to 125-Ton

- Capability to cam-pierce, draw, press-form, offset, lance, pierce, & notch

- Some of Star’s piercing equipment has automatic feeders for rapid punch

Miter-to-size:

- Miter saws

- Can cut compound miters

- Precision straight & miter cuts

- Compound miters & V-notch saws

Machining & tapping:

- Star has horizontal & vertical machining centers

- High-speed tapping machines

- High speed machining centers

- 4th Axis machining

Drilling:

- Drill, countersink, & counterboring

- Custom & dedicated drill machines

Deburring:

- End-deburr & Vibro-deburr application

- Double-head deburring machines

Special machines & welding:

- Custom equipment designed per project or application

Fabrication staff:

- Star’s high-quality staff has decades of combined experience to match & operate the superior equipment.

What else sets Star apart in the fabrication department?

Many U.S. based aluminum extruders do not offer this level of fabrication in-house. Saving customers time, money, and paperwork, streamlining communication and reducing the number of purchase orders, are just some of the benefits of using Star for your one-stop shop for aluminum extruded fabrication.

Star does it all, not just aluminum extruded fabrication!

Not only do they offer extrusion, fabrication, finishing, and complete assembly, Star also offer packaging and shipping.

- Hundreds of packaging specs

- No volume is too large or small

- Shipments delivered on time, every time

- Ship to you or your customer

- Star’s fleet of modern trucks loaded with quality products for delivery guarantees customer satisfaction

More About Star Extruded Shapes

Star Extruded Shapes is a premiere one-stop shop for all your extruded aluminum fabrication needs and other aluminum extrusion services. Serving a wide range of markets, we offer high-quality, competitively priced products backed by exceptional customer service. We prioritize timely delivery to ensure complete customer satisfaction. Our commitment to innovation and excellence in design and manufacturing sets us apart as a top choice for custom aluminum fabrication projects.

Contact our team today to discuss your project requirements and needs. Our team is ready to get a quote together for you either online or call them at (330) 533-9863. Take the extra steps and guesswork out of your next aluminum extrusion project with Star Extruded Shapes.

Dive even deeper and learn more about aluminum extrusions and the processes: https://aec.org/glossary

Follow Star Extruded Shapes on socials!

Facebook: https://www.facebook.com/profile.php?id=100063753529991

LinkedIn: https://www.linkedin.com/company/star-extruded-shapes

YouTube: https://www.youtube.com/channel/UCep7i_8CZmfokXdXkGEhRJw