Imagine bringing your aluminum extrusion project to life seamlessly, with every step handled by a single experienced provider and no juggling multiple vendors, managing fragmented communication, or worrying about delays. That’s the power of turnkey aluminum extrusions from Star Extruded Shapes. We handle everything from crafting custom aluminum profiles and standard aluminum extrusions to complete assembly, packaging, and aluminum shipping. Customers can forget the hassle and focus on their vision; our services will translate it into reality.

What are the Advantages of Turnkey Aluminum Extrusions?

Turnkey aluminum extrusions come ready for immediate use or installation upon delivery to the customer. This comprehensive service, where the same supplier handles manufacturing, fabrication, finishing, and assembly, streamlines the process by removing the need for multiple vendors. It effectively reduces the risk of errors, delays, and additional costs, ensuring a smoother project flow from start to finish.

More Than Just Extrusions: A One-Stop Aluminum Shop

Star stands as a comprehensive aluminum fabrication expert in Ohio, delivering wide-range of extrusion solutions across various sectors such as automotive, aerospace, medical, and construction. With the capability to manage projects demanding high precision, quality, and performance, the company specializes in turnkey extrusions tailored to diverse requirements and specifications, addressing complex and challenging needs efficiently.

The organization’s range of services extends beyond extrusion, encompassing a complete set of solutions:

Design and engineering: Star works closely with clients, tailoring aluminum extrusion and fabrication to meet specific needs through design assistance and engineering support. Whether a customer comes to the company with a full fabrication print or just part of an idea, Star leverages CAD and CAM technologies to refine and realize the precise design requirements envisioned.

Extrusion: Armed with state-of-the-art presses, Star has the capability to extrude aluminum profiles ranging from .100 up to 10+ lbs. per foot, accommodating profiles up to 16 inches in width. This flexibility allows for both standard and custom aluminum profiles, utilizing a variety of alloys and tempers tailored to meet customer-specific requirements. Star ‘s aluminum products are enhanced with secondary operations like cutting, drilling, punching, bending, and machining, ensuring further customization and refinement.

Aluminum fabrication for extrusions: Equipped with advanced CNC machinery and operated by skilled experts, our facility can perform a wide array of operations including milling, turning, tapping, and threading. This setup allows to produce custom aluminum parts, ranging from simple to complex designs, with exceptional precision and tight tolerances. Star extends its services with global component parts purchasing, enabling the sourcing and procurement of additional parts or components required for customer products, including fasteners, hinges, brackets, and more, to ensure comprehensive project fulfillment.

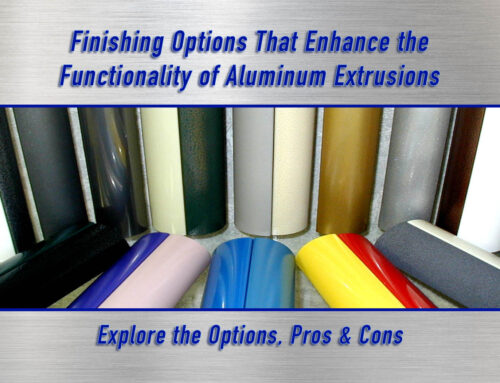

Aluminum finishing: Star comes full circle with in-house finishing services, offering anodized aluminum extrusions, powder coating, and liquid painting for varied colors, textures, and effects to enhance appearance and durability. Additional services include labeling, marking, and engraving for logos, codes, or product information.

From Standard Shapes to Bespoke Solutions: “We Do It All”

Whether customers need standard aluminum profiles for a straightforward project or require custom aluminum extrusions for a one-of-a-kind vision, Star has you covered. Skilled engineers collaborate with customers to design and produce extrusions that meet specifications.

Complete Assembly Capabilities: Bringing Visions to Life

Star’s turnkey service optimizes the journey from design to final assembly for aluminum extrusions, accommodating any order size efficiently and cost-effectively. This service includes direct shipping to customers and leverages global purchasing for necessary components like DVDs, castings, molded parts, fasteners, springs, shafts, pins, specialty items, rods, struts, instruction manuals, labeling, and logo recognition.

A sophisticated inventory system and the synergy between engineering and sales teams ensure smooth assembly process execution, tailored to precise customer specifications with speed.

Aluminum Extrusion Packaging and Shipping: Delivering Projects with Care

Equipped with a diverse range of standard and customized packaging solutions, Star ensures every order, from bare bundles to secure crates, meets customer preferences. With hundreds of packaging specifications, Star caters to orders of all sizes and ensures timely delivery of shipments. The customers can receive the orders themselves or have them shipped directly to their clients. Our fleet of modern trucks ensures that the customers receive the orders in perfect condition and are satisfied with the delivery process.

Experience the Star Difference: A Turnkey Aluminum Solution

Partnering with Star, a full-service aluminum extruder, means unparalleled convenience, efficiency, and quality. We strive to streamline the process, enabling a focus on innovation and project realization. Contact us today to discuss your needs and discover how our turnkey aluminum extrusions can transform your ideas into reality.

More about Star Extruded Shapes

Star is a leading one-stop shop for all things aluminum extrusion and supporting services. We serve a wide range of markets with our comprehensive services. We are known for our high-quality, competitively priced products and exceptional customer service, we ensure timely delivery and customer satisfaction. Our commitment to innovation and excellence in design and manufacturing sets them apart as a top choice for aluminum extrusion projects.

Let’s Connect:

Facebook: https://www.facebook.com/profile.php?id=100063753529991

LinkedIn: https://www.linkedin.com/company/star-extruded-shapes