Powder coating is a cutting-edge finishing technology that has transformed the manufacturing landscape. But what exactly is powder coating? Let the leading full-service provider of aluminum extrusions, Star Extruded Shapes, Inc., guide you through the nuances of powder coating—specifically, powder coated aluminum extrusions—its benefits, and how we leverage over three decades of expertise to deliver top-notch powder coating services.

What Is Powder Coating?

Powder coating is a type of coating that is applied as a free-flowing, dry powder that was invented in the 1940s. It is a process that coats an object electrostatically and then is cured with heat, creating a finish harder, potentially thicker, and tougher than conventional paint.

Originally it was used by metal manufactures on products such as household appliances, aluminum extrusions, drum hardware, automobile parts, and bicycle frames, the practice of powder coating has been expanded to allow finishing of other materials as the technology and processes evolved. Powder coating is mainly used for coating of metal objects, particularly those subject to rough use.

Understanding The Advantages of Powder Coated Aluminum Extrusions

Because powder coating does not have a liquid carrier, it can produce thicker coatings than conventional liquid, without running or sagging, and powder coating produces minimal appearance variations between horizontally coated surfaces and vertically coated surfaces.

Additionally, several powder colors can be applied before all are cured together, allowing color blending and special bleed effects in a single layer. The application process is efficient, allowing for quick and uniform coverage. From an environmental perspective, no carrier fluid evaporates away, allowing the coating process to emit very little volatile organic compounds (VOC).

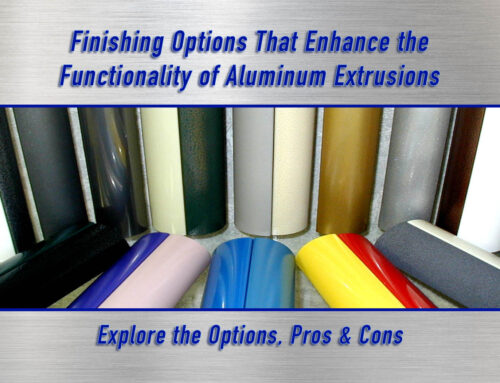

Overall, powder coated aluminum extrusions offer numerous benefits. It is versatile providing aesthetic appeal, a variety of color finish and surface texture options, as well as resistance to corrosion, chipping, fading, scratching, and wearing. This durability makes it well-suited for metal parts that are exposed to sunlight and other environmental factors. Furthermore, powder coating is more environmentally friendly and cost-effective, making it a popular choice for manufacturers and designers.

What Does Star Offer with Powder Coating?

At Star Extruded Shapes, we pride ourselves on our comprehensive expertise and state-of-the-art powder coating facilities. We ensure top-quality finishes that not only meet but exceed industry standards. Our services encompass everything from thorough pre-treatment to advanced application techniques and stringent post-coating quality checks. Our services are as follows:

- ISO 9001:2015 certified

- Powder Coating Line product maximum size 30’ long and 6’ high

- Horizontal line application

- RoHS-compliant coatings and treatments

- Bulk chemical system

- Dry-in-place non-chrome sealer pre-treatment

- Combination infrared and convection oven for faster cure of powder

- Offline racking for processing of small parts

- Color verification

- 12 GPM reverse osmosis water system for final rinse

- 12 automatic and 2 hand-spray units

- Batch booth for fast processing of customer samples

- In-house rack-making capability

- Multi-stage pre-treatment

- Dry film lubricants

Aluminum Extrusion Pre-Treatment

Our premium aluminum extrusion undergoes an extensive pre-treatment process to ensure maximum quality and longevity. This involves the application of chemical solutions to remove dust, grease, and other foreign particles. This crucial step sanitizes the extruded parts, promoting proper adhesion and preventing flaking to achieve a flawless finish.

Application of Powder Coating

After pre-treatment, the aluminum extrusions move to the next critical phase. During the application of powder coating, powder consisting of colored pigment and resin is applied using an electrostatic spray gun. This positive charge makes the powder bond with an electrically grounded extrusion. Alternative methods such as electrostatic magnetic brush, electrostatic discs, and fluidized bed techniques are also available, each offering unique benefits depending on the application requirements.

Curing and Cooling of Extrusion Products

Extrusions are then baked in a large curing oven for a set duration and set temperature, causing the powder to melt uniformly, and forming a hard coating when cooled. The powders cure at 300°F to 400°F for 10 to 15 minutes at part temperature. The heat in the oven will cause the powder to melt and form a plastic sheet around the part. At this point, the powder bonds not only to itself but to the part as well.

Star ensures that every part receives the proper attention. After the material has cooled to the appropriate temperature, the result is a smooth, hardened coating. Once the material has cooled it is inspected for quality control.

Powder Coating Finish

“Which type of finishing do I need for my aluminum extrusion?”

At Star Extruded Shapes, Inc., we recognize that different products require different finishes. Our powder coating processes are not only comprehensive but tailored to meet the specific needs of your products. Whether you require a specific finish for functionality or style, Star can guide you through selecting the best process for your application.

Comprehensive Capabilities of Star

Powder coating is just one of the many services that allow Star to stand out as a full-service aluminum extruder. We offer complete turn-key experience, from the initial consultation to the final delivery, ensuring that all your needs are met comprehensively and efficiently.

More about Star Extruded Shapes

Star Extruded Shapes stands as a leading one-stop shop for all things related to aluminum extrusion and its supporting services. We cater to a diverse array of markets with our comprehensive offerings. Renowned for delivering high-quality, competitively priced products coupled with exceptional customer service, we prioritize timely delivery to ensure complete customer satisfaction. Our unwavering commitment to innovation and excellence in design and manufacturing distinguishes us as a top choice for aluminum extrusion projects.

Let’s Connect!

Contact our team today to discuss your project requirements and get a quote. Discover why countless clients choose their exceptional services. Don’t hesitate to contact Star and take the first step towards the success of your project!

Facebook: https://www.facebook.com/profile.php?id=100063753529991

LinkedIn: https://www.linkedin.com/company/star-extruded-shapes